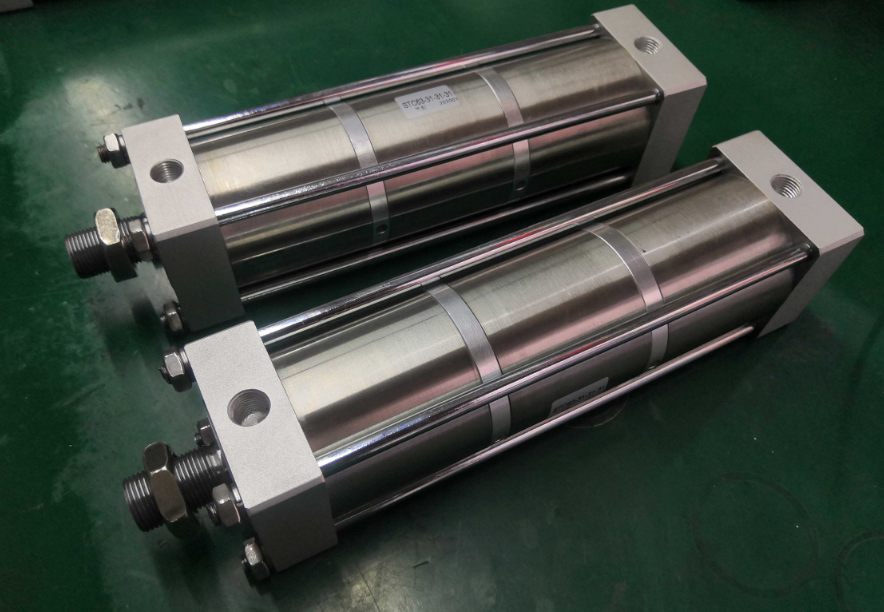

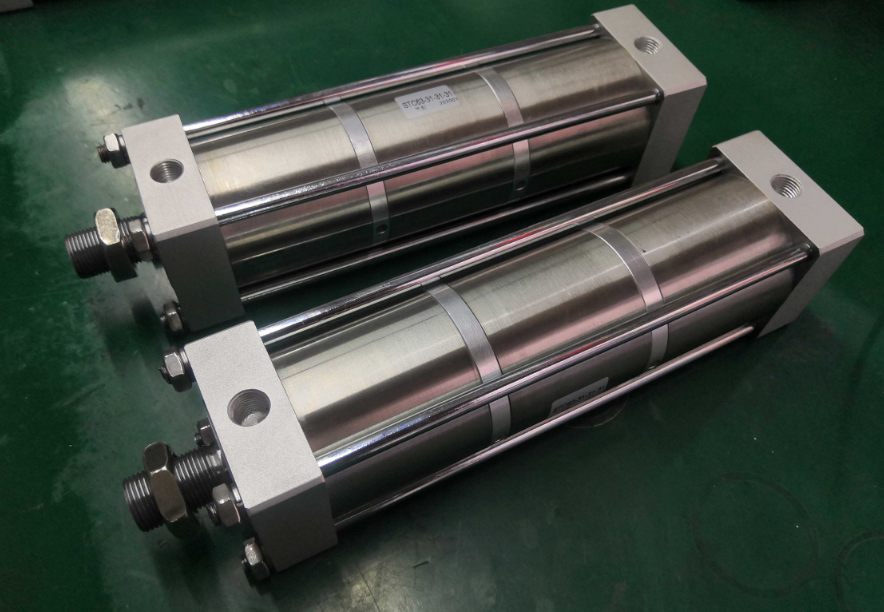

In the fields of modern industrial automation and mechanical manufacturing, cylinders, as important executive components, have a crucial impact on the performance and efficiency of the entire production system. Aluminum side push cylinders have gradually become the preferred choice for many industrial applications due to their lightweight design and efficient power output.

1、 The advantages of lightweight design

The aluminum side push cylinder is made of aluminum alloy material, which has significant lightweight advantages. The density of aluminum is about one-third that of steel, and using aluminum materials can significantly reduce the weight of cylinders. This can reduce the overall load and improve energy efficiency for equipment and machinery with strict weight requirements, such as material handling devices in automated production lines and related equipment in the aerospace industry. For example, SMC's MGPM80-75Z-M9PV cylinder model achieved a weight reduction of up to 24% through shortened guide rods and changes in end plate thickness, which is crucial for improving energy efficiency and response speed.

In addition, the aluminum side push cylinder also has good heat dissipation performance, which can quickly dissipate the heat generated inside, avoiding the performance degradation or failure of the cylinder due to overheating, and extending the service life of the cylinder. It is easy to form a dense aluminum oxide protective film on its surface, which has strong corrosion resistance and can maintain good performance even in humid or corrosive media such as acid and alkali.

2、 Efficient power output

Aluminum side push cylinders can provide stable thrust and high-precision displacement control, meeting various needs in industrial automation production. Its internal structure is mainly composed of a cylinder, a piston, a piston rod, seals, etc. The piston is driven by compressed air to move inside the cylinder, thereby driving the piston rod to extend or retract, producing lateral linear motion. This type of motion allows the side push cylinder to achieve efficient and precise power transmission within a limited space.

Aluminum side push cylinders are widely used in industrial automation production lines for material pushing and positioning, component assembly, fixture opening and closing control, and other scenarios. For example, in the assembly process of electronic products, the side push cylinder can accurately push electronic components from one workstation to another, ensuring the continuity and efficiency of the production process. In the field of automobile manufacturing, side push cylinders can be used for the assembly of automotive components, such as accurately aligning the engine cylinder block and cylinder head to ensure assembly quality.

3、 Application scenarios and development directions

Aluminum side push cylinders have a wide range of applications, covering multiple fields such as industrial automation production lines, logistics and warehousing, food and packaging, medical equipment, mechanical equipment and instrumentation. For example, in logistics sorting systems, aluminum side push cylinders can be used to sort different types or destinations of goods from conveyor belts; On the food processing production line, it is used for processes such as filling, sealing, and labeling of food.

With the continuous development of industrial automation technology, aluminum side push cylinders are also constantly innovating and upgrading. In the future, aluminum side push cylinders will develop towards intelligence, high precision, green environmental protection, miniaturization, and integration. For example, by installing intelligent sensors on the cylinder, the operating status of the cylinder can be monitored in real time, such as position, pressure, speed and other parameters, and these data can be fed back to the control system to improve the reliability and stability of the equipment.

4、 Summary

Aluminum side push cylinders have become an ideal choice in the fields of industrial automation and mechanical manufacturing due to their lightweight design and efficient power output. Its widespread application in multiple fields has demonstrated its advantages in improving production efficiency, reducing energy consumption, and extending equipment lifespan. With the continuous advancement of technology, aluminum side push cylinders will continue to play an important role in the field of industrial automation, providing strong support for the development of modern manufacturing.

Prev:Pressure Gauge: Accurate measurement, assisting in efficient production

Next:Correct use and maintenance of pressure gauge