In modern industrial production, the Pressure Gauge, as an important measuring tool, is widely used in various fields. It can accurately measure gas pressure, ensuring the normal operation of equipment and efficient production process. The pressure gauge is not only related to production efficiency, but also directly affects production safety and product quality. This article will provide a detailed introduction to the importance and application of Pressure Gauges in industrial production.

1、 The function of a Pressure Gauge

(1) Ensure the normal operation of the equipment

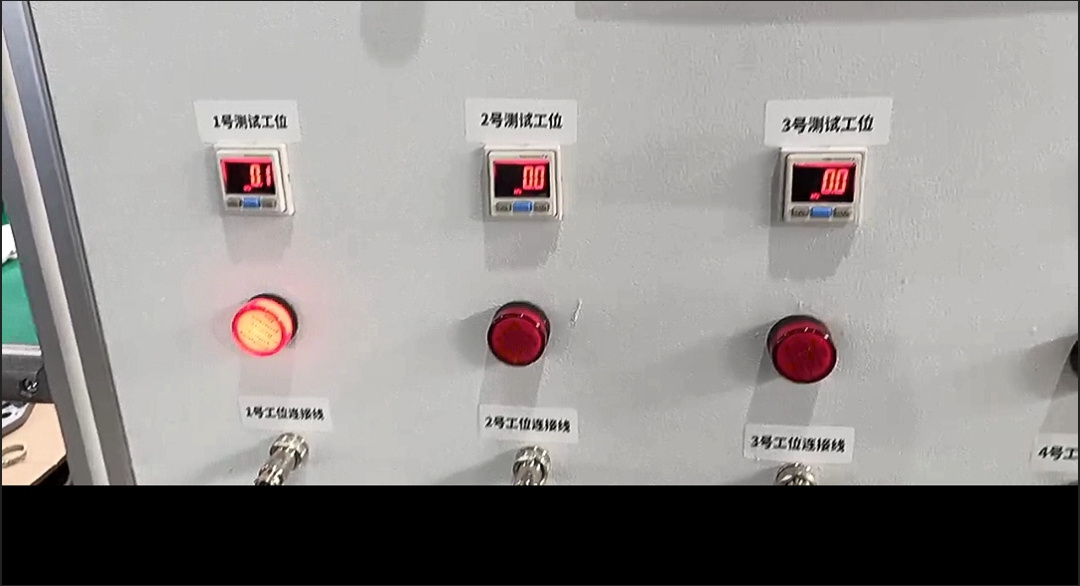

In industrial production, many devices rely on pneumatic systems to drive and control. For example, pneumatic tools, cylinders, pneumatic valves, etc. all require precise air pressure to ensure their normal operation. The pressure gauge can monitor the air pressure in real time, ensuring that the equipment operates within the set pressure range and avoiding equipment failure caused by high or low air pressure.

(2) Ensure production safety

High air pressure may cause equipment damage or even explosion, while low air pressure may affect the normal operation of equipment and even lead to production accidents. By installing a pressure gauge, abnormal air pressure can be detected in a timely manner and corresponding measures can be taken to ensure production safety.

(3) Improve production efficiency

Accurate pressure measurement can ensure the stability of the production process. For example, in an automated production line, a pressure gauge can monitor air pressure in real-time, ensuring efficient operation of pneumatic equipment, reducing downtime, and improving production efficiency.

2、 Application Fields of Pressure Gauges

(1) Manufacturing industry

In manufacturing industries such as automobile manufacturing and mechanical processing, pressure gauges are widely used for monitoring pneumatic tools, cylinders, and valves. Through precise pressure measurement, the efficient operation of equipment can be ensured, improving production efficiency and product quality.

(2) Chemical industry

In chemical production, many reactions require specific gas pressures to be carried out. The pressure gauge can monitor the pressure inside the reaction vessel in real time to ensure stable reaction conditions. In addition, a pressure gauge can also be used to monitor the air pressure inside pipelines to prevent leaks and explosion accidents.

(3) Food processing industry

During the food processing, a pressure gauge is used to monitor the air pressure of packaging equipment, ensuring the sealing and safety of the packaging. For example, in a beverage filling production line, a pressure gauge can ensure the stability of the filling process and avoid packaging leaks caused by pressure fluctuations.

(4) Medical industry

In medical equipment, a Pressure Gauge is used to monitor the air pressure of devices such as ventilators and anesthesia machines. Accurate pressure measurement can ensure the normal operation of equipment and ensure the safety of patients.

3、 Maintenance and upkeep of the Pressure Gauge

(1) Regular calibration

The accuracy of the pressure gauge is the key to ensuring production safety and efficiency. Therefore, regular calibration of the pressure gauge is essential. It is recommended to calibrate every 6 or 12 months to ensure its measurement accuracy.

(2) Cleaning and Inspection

Regularly clean the surface and pressure sensing components of the pressure gauge to prevent dust and impurities from affecting measurement accuracy. At the same time, check whether the connection part of the pressure gauge is loose or damaged, and repair or replace it in a timely manner.

(3) Environmental adaptability

The pressure gauge should be installed in a dry, non corrosive gas environment to avoid equipment damage caused by environmental factors. If the pressure gauge needs to be used in harsh environments, a model with protective functions should be selected.

4、 Summary

Pressure Gauges play an important role in industrial production. Through precise pressure measurement, the pressure gauge can ensure the normal operation of equipment, guarantee production safety, and improve production efficiency. Choosing the appropriate pressure gauge and conducting regular maintenance and upkeep is the key to ensuring smooth production. With the continuous advancement of technology, the application of intelligent Pressure Gauges will become increasingly widespread, providing stronger support for industrial automation and intelligent management.

Prev:How to choose the appropriate solenoid valve

Next:Aluminum side push cylinder: the perfect combination of lightweight and efficient power