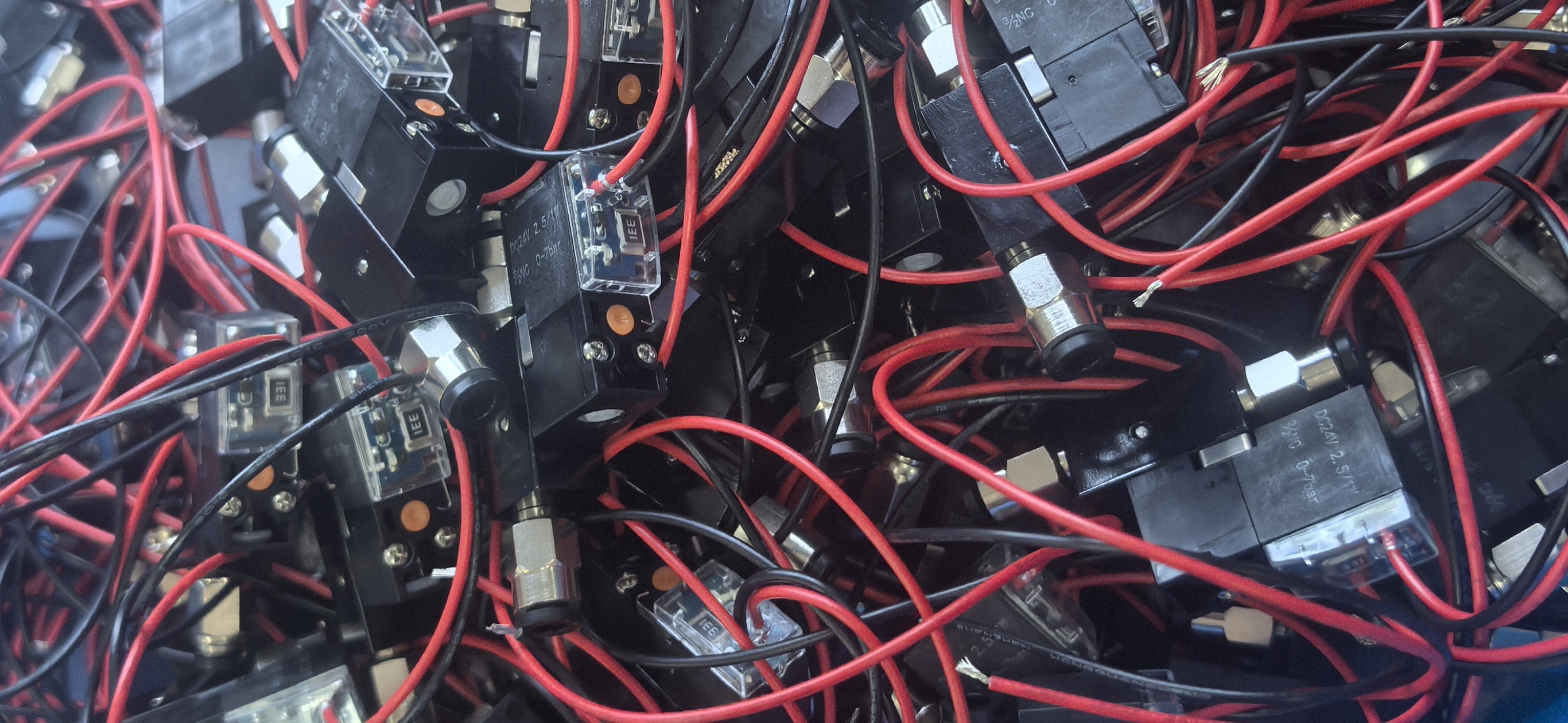

When selecting a suitable solenoid valve, multiple factors need to be considered comprehensively, including application scenarios, technical parameters, environmental conditions, etc. Here is a detailed guide for selecting solenoid valves:

1、 Clearly define the application scenario

There are different types of solenoid valves according to different application scenarios. The following are common application scenarios and corresponding types of solenoid valves:

Water solenoid valve: suitable for water supply and drainage, fire protection, agricultural irrigation and other systems.

Steam solenoid valve: suitable for boiler, heating, disinfection and other systems.

Refrigeration solenoid valve: suitable for air conditioning, cold storage and other systems.

Gas solenoid valve: suitable for systems such as gas stoves and water heaters.

Hydraulic solenoid valve: suitable for hydraulic machinery, engineering machinery and other systems.

Explosion proof solenoid valve: suitable for explosive environments such as oil fields, mines, etc.

2、 Consider technical parameters

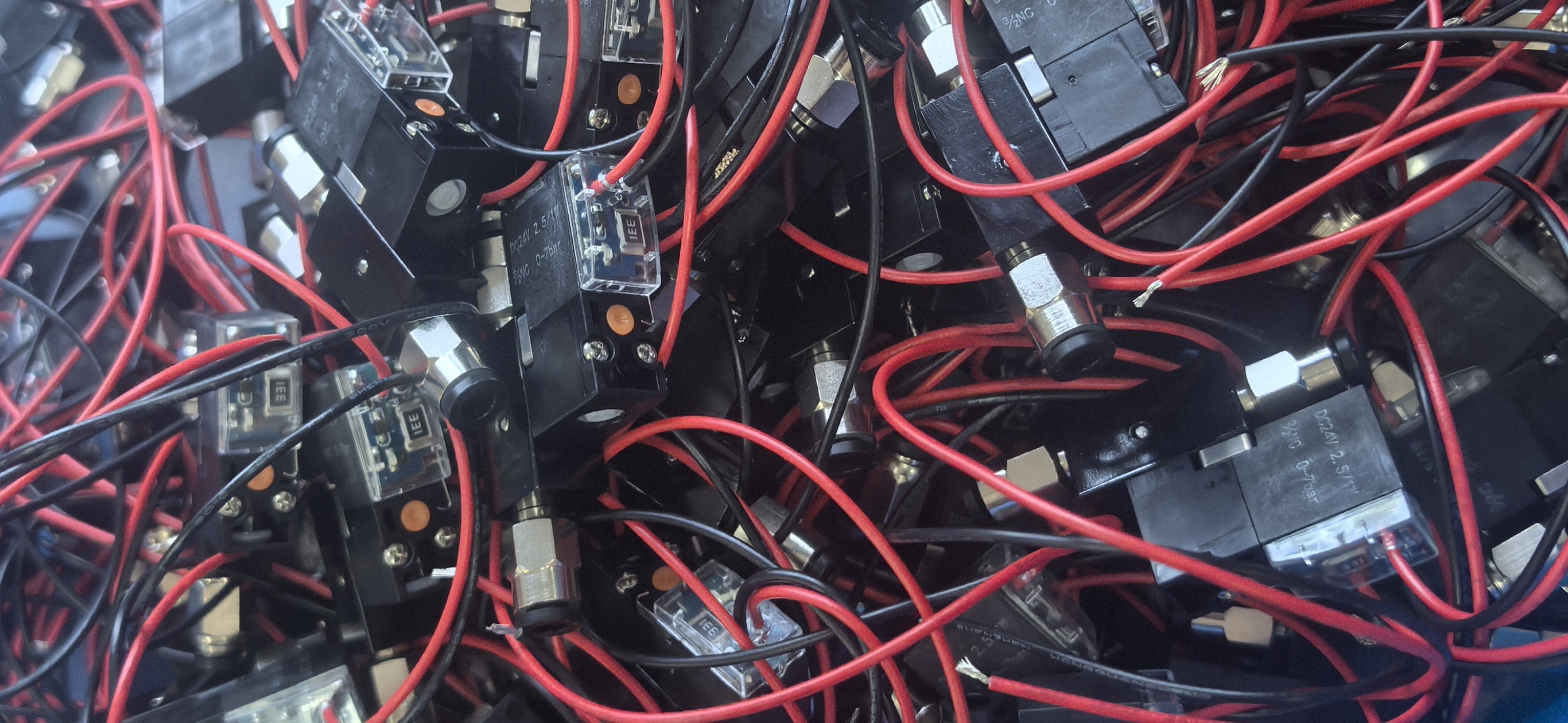

Rated voltage: The rated voltage of the solenoid valve is a key parameter for its normal operation. The common voltage specifications include AC220V and DC24V, which should be selected according to the actual power supply conditions.

Diameter size: Determine the diameter (DN) of the solenoid valve based on the inner diameter or flow requirements of the pipeline. When DN ≤ 50mm, threaded interface can be selected, and when DN>50mm, it is recommended to choose flange interface.

Work pressure: Select the type of solenoid valve based on the system's working pressure. Low pressure systems (≤ 0.04MPa) are suitable for direct acting or step-by-step direct acting solenoid valves, while high-pressure systems (≥ 10MPa) require the selection of pilot piston solenoid valves.

Medium characteristics: Select the appropriate solenoid valve material and structure based on the type of medium (such as gas, liquid, corrosive fluid, etc.), temperature, viscosity, etc. For example, corrosive fluids require the selection of corrosion-resistant materials (such as stainless steel).

Action mode: The normally closed solenoid valve closes when powered off and opens when powered on; Normally open solenoid valves are the opposite. Choose the appropriate action method based on actual needs.

3、 Environmental conditions

Temperature and humidity: If the solenoid valve is to be used in high or low temperature environments, a model with good temperature resistance should be selected; Waterproof solenoid valves should be selected in damp or underwater environments.

Explosion proof requirements: In explosive environments, explosion-proof solenoid valves must be selected to ensure safety.

Installation direction: Some solenoid valves (such as step-by-step direct acting) need to be installed vertically to prevent gravity from affecting the reset of the valve core.

4、 Other precautions

Response time: The response time of solenoid valves is usually between 10 and 1000 milliseconds. If the system has high requirements for response speed, a direct acting solenoid valve should be selected.

Leakage rate: Leakage rate is an important indicator for measuring the sealing performance of solenoid valves, and solenoid valves with leakage rates that meet the requirements should be selected.

Brand and after-sales service: Choosing well-known brands and solenoid valves with good after-sales service can ensure product quality and technical support during use.

Through the above steps, you can choose the appropriate solenoid valve according to your specific needs to ensure that it can work stably and reliably in the system.

Prev:Cylinder Troubleshooting: Quick Diagnosis and Maintenance Techniques

Next:Pressure Gauge: Accurate measurement, assisting in efficient production