In the field of industrial automation, compact equipment design and stable operational precision are two core requirements. Compact guide rod cylinders, with their key advantages of "strong resistance to misalignment" and "non-declining long-term operational accuracy," have become an ideal choice for scenarios such as electronic manufacturing, automotive parts assembly, and precision inspection, effectively addressing numerous practical challenges in automated production lines.

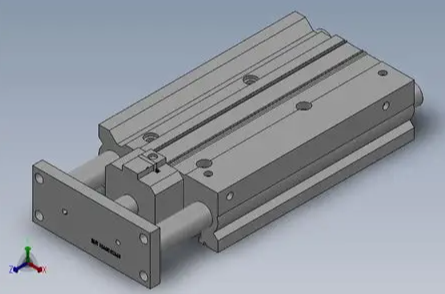

From a structural design perspective, the compact guide rod cylinder's resistance to off-center loading stems from its unique dual-rod parallel layout. Compared to traditional single-rod cylinders, it rigidly connects the cylinder body with two high-precision guide rods, forming a stable "dual-support structure." When the cylinder bears lateral loads or eccentric forces, the dual guide rods can evenly distribute the applied force, preventing the piston rod from bending or shifting due to unilateral stress.Taking electronic component insertion equipment as an example, when the cylinder drives the fixture to pick up components, lateral forces often arise from positional deviations of the components. Traditional cylinders are prone to positioning deviations, leading to increased insertion error rates. In contrast, the compact guide rod cylinder leverages the off-center loading resistance of its dual guide rods to ensure the fixture maintains precise alignment, keeping the error rate below 0.1%. Additionally, the guide rods are chrome-plated and paired with high-precision linear bearings, further reducing friction coefficients and minimizing the impact of off-center loads on motion trajectories. This enables the equipment to maintain stable performance during continuous operation.

The long-term operational accuracy without degradation represents a dual breakthrough in material selection and sealing technology for Compact Guide Cylinders. The cylinder body is formed through die-casting with high-strength aluminum alloy, significantly enhancing overall rigidity after aging treatment, effectively resisting vibration and stress deformation during prolonged operation. The piston rod is made of SUS304 stainless steel, precision-ground to maintain a surface roughness of Ra0.2μm or less, ensuring excellent straightness even after extended sliding. More crucially, its sealing system employs a multi-layer composite structure—inner polyurethane seals ensure airtightness, while outer dust seals block dust and oil contamination, preventing impurities from entering the cylinder body and causing wear.

In practical applications, the two major advantages of compact guide rod cylinders can also be deeply integrated with automation systems. For instance, in the gripping stations of small robotic arms, the cylinders need to frequently extend and retract within confined spaces while withstanding eccentric forces generated by lifting heavy loads. Their resistance to off-center loads ensures precise robotic arm movements and prevents workpiece detachment. Meanwhile, long-term operational precision without degradation guarantees stable production line cycle times, eliminating the need for frequent shutdowns for calibration and thereby improving overall production efficiency. Whether in the precision assembly of 3C products or the component processing of medical devices, compact guide rod cylinders, with their "small size and high performance" characteristics, provide reliable power support for industrial automation upgrades, making them a crucial equipment choice for cost reduction and efficiency enhancement in enterprises.

Prev:Which companies hold a leading position in the Chinese wire harness industry?

Next:Working Principle of Automotive Wiring Harness Test Bench