I.

Core production process

1.

Engineering design stage

3D

wire laying: CATIA/Electric Harness Design module simulates the

wiring of the whole vehicle.

Lead

wire selection: select wire diameter according to current load

(0.13mm²~120mm²)

Terminal

matching: AMP/TE Connectivity database selection (gold plated/tin

plated/silver plated)

Protective

design: Bellows (Φ5~Φ80), tape wrapping (PVC/ fabric base / flannelette)

II.

Preparation of raw materials

Pre-treatment

of wires: stranding of copper wires→extrusion of insulation

layer (XLPE/PVC)→laser coding (wire number + batch)

Stamping

of terminals: continuous die stamping of 0.5mm copper tape (accuracy ±0.01mm)

Manufacture

of injection molded parts: PA66+GF30 material injection connector

shell (waterproof grade IP6K9K)

III.

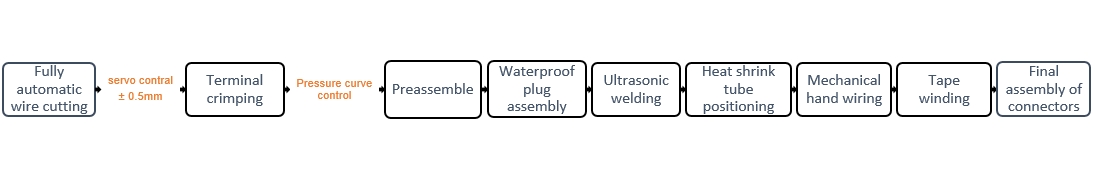

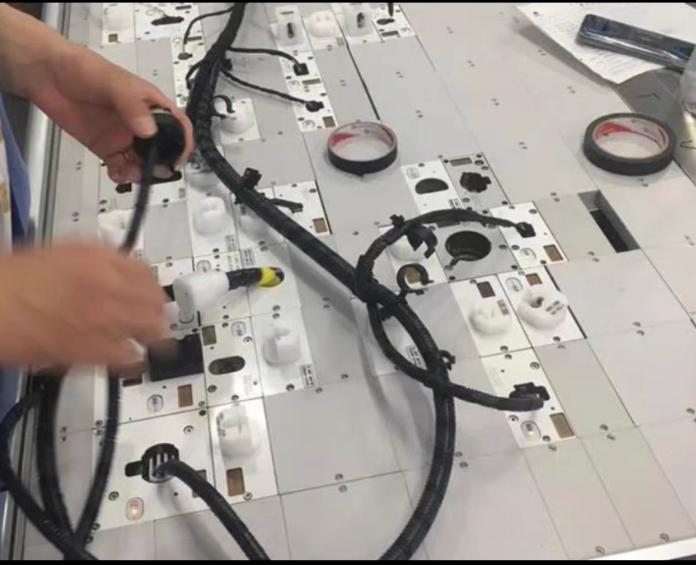

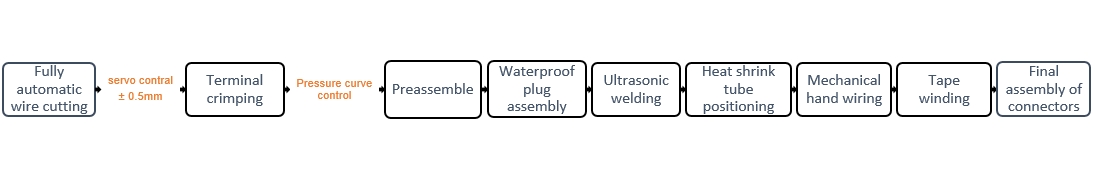

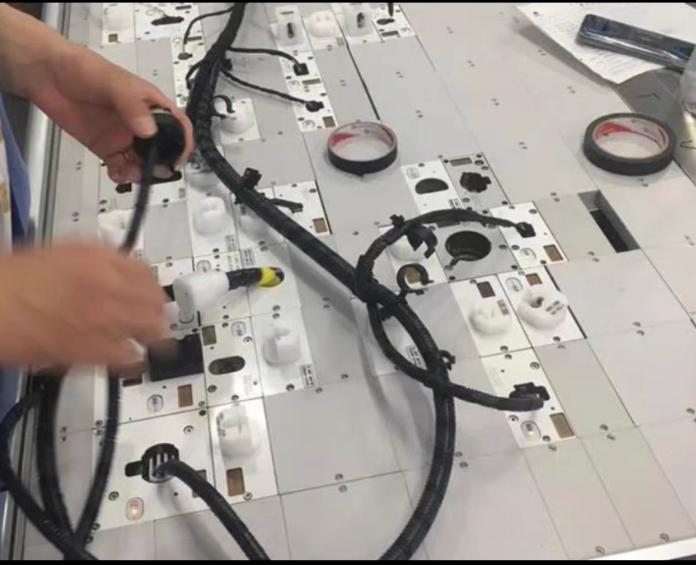

Wire harness assembly line

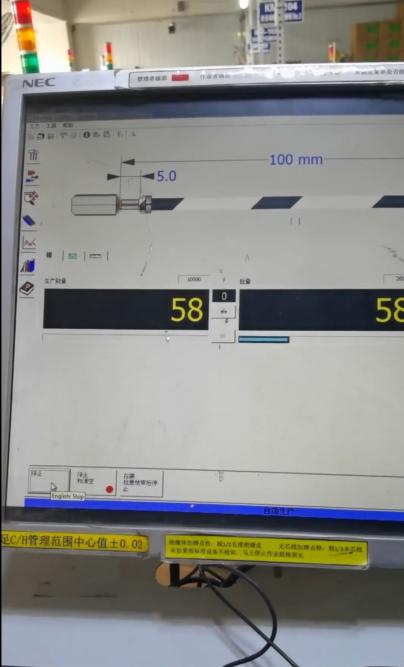

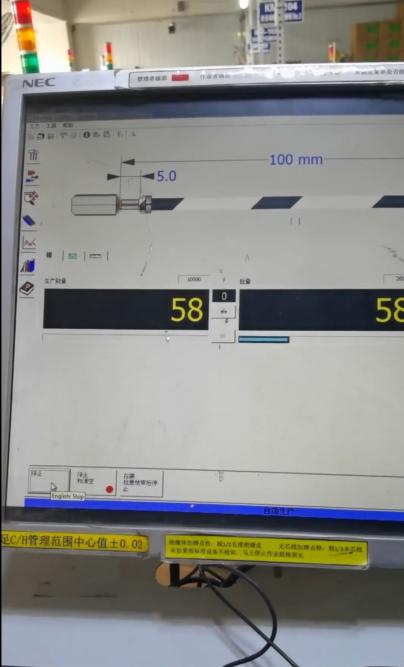

Key

process control points:

Crimp

height: 0.8±0.03mm (micrometer sampling inspection)

Tensile

test: wire and terminal>80N

(ISO 8092 standard)

Conductivity

test: 100% full inspection (resistance <10mΩ)

IV.

Quality verification system

Electrical

test:

Voltage

withstand test: AC 1500V/3s (insulation resistance >100mΩ)

Instantaneous

break detection: microsecond break monitoring in vibration

Environmental

test:

Temperature

cycling: -40℃↔125℃/1000 times (ISO 16750)

Salt

spray test: 96h@5% NaCl solution

Tag:

Prev:Dual Digital Display Fiber Optic Sensor Use Instructions and Technical Points

Next:Introduction to cylinder detection methods ------Watertight test