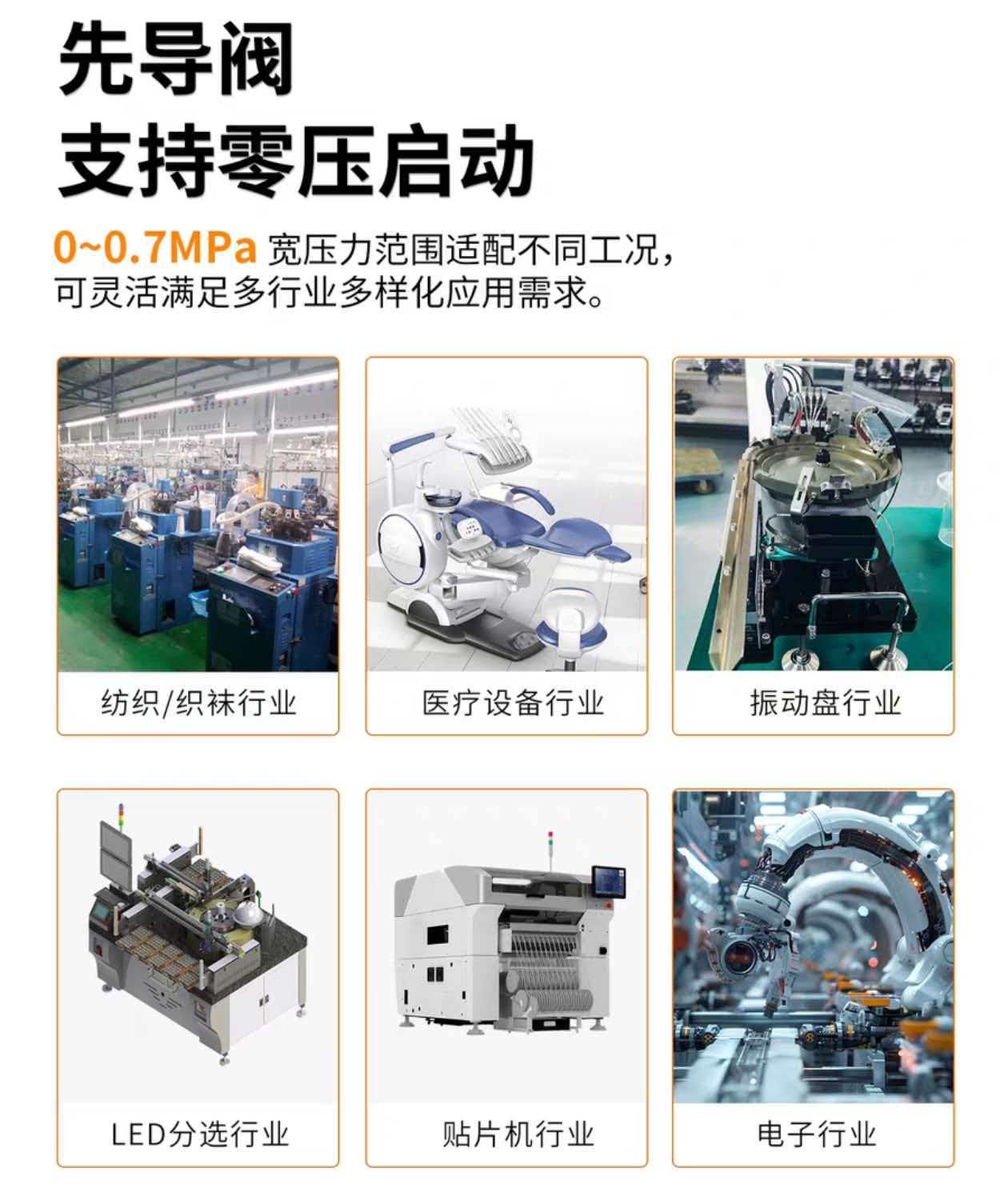

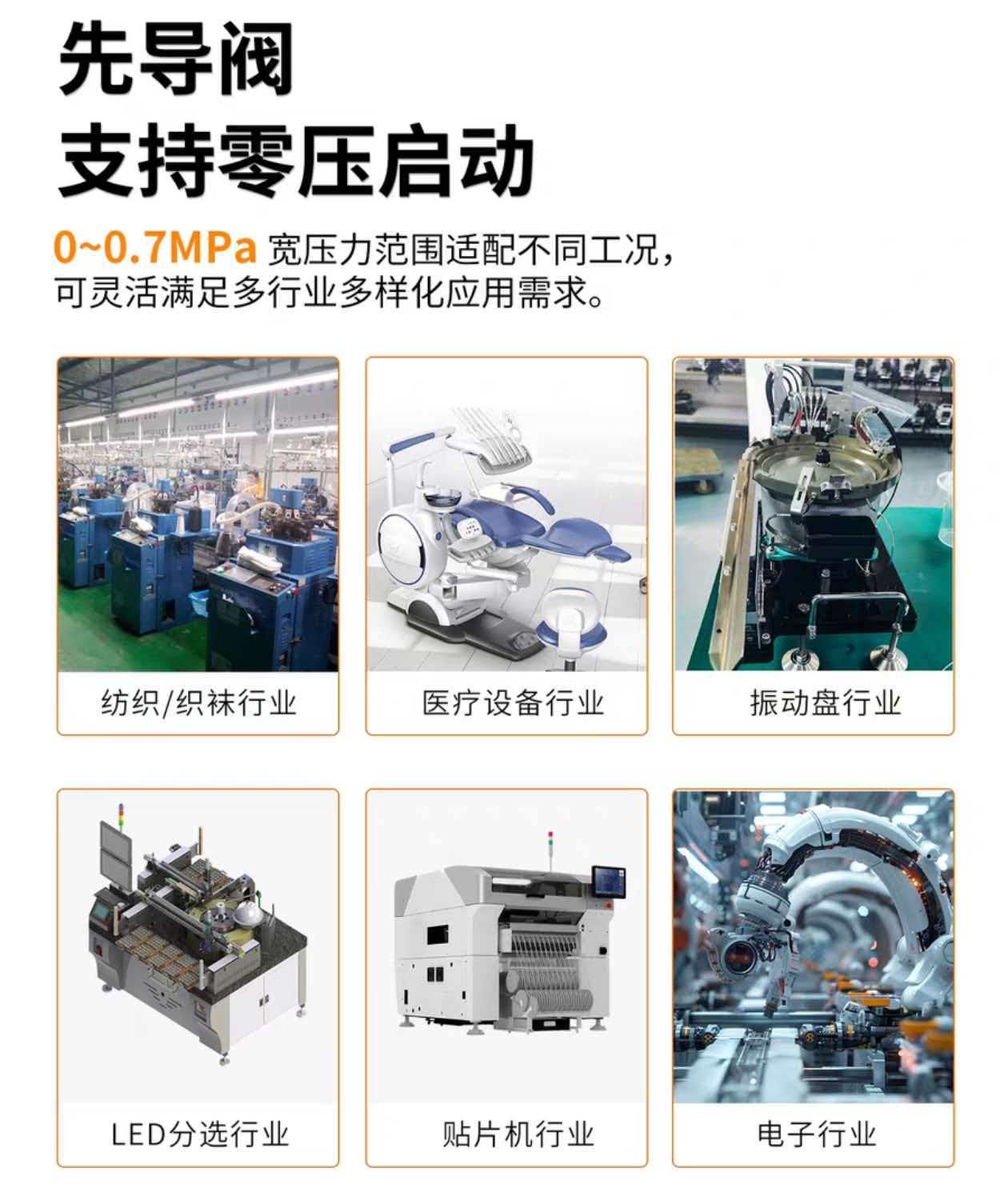

In industrial automation assembly lines, the precision and stability of fluid control directly determine production efficiency and product quality. Micro solenoid valves, with their core advantages of small size, fast response, and precise control, have become key core components for material conveying, pressure regulation, and process linkage in assembly lines. At the same time, the complex working environment of the assembly line (such as dust, vibration, temperature fluctuations, etc.) places strict requirements on the reliability of micro solenoid valves, and scientific application selection and protection strategies are crucial.

Micro solenoid valves present diversified application scenarios in industrial automation assembly lines, with core values focused on precise control and efficient collaboration. In the material conveying process, it can accurately regulate the on/off and flow of power media such as compressed air and hydraulic oil, achieve precise linkage of conveyor belt start/stop, mechanical arm grasping and other actions, and ensure efficient flow of materials between various processes; In precision machining scenarios, micro solenoid valves control the precise injection of cutting fluid and coolant through high-frequency response (millisecond level), matching the machining rhythm and improving machining accuracy and tool life; In the automated detection process, it can cooperate with sensors to achieve real-time adjustment of medium pressure and flow rate, ensuring stable operation of detection equipment and guaranteeing product quality inspection pass rate. In addition, the small size of micro solenoid valves can adapt to the compact installation space of assembly lines, reduce the difficulty of equipment integration, and assist in the lightweight design of assembly lines.

The complex working conditions of industrial automation assembly lines can easily lead to micro solenoid valve failures, and a targeted protection system needs to be constructed. To address the issue of dust and impurity pollution, a high-precision filtering device should be installed at the inlet of the solenoid valve, and the filter element should be cleaned regularly to prevent impurities from entering the valve body and causing wear on the seals and valve core; For vibration interference, a micro solenoid valve with anti vibration fixing structure should be selected, and a buffer gasket should be added during installation to avoid the transmission of assembly line vibration to the valve body and affect the accuracy of valve core action, while reducing the risk of loose wiring.

Temperature fluctuations and medium corrosion are another major protection focus. In high-temperature working conditions (such as metallurgy and injection molding lines), micro solenoid valves made of high-temperature resistant materials (such as high-temperature alloys and fluororubber seals) should be selected, and the installation layout should be optimized to stay away from heat sources or install heat shields; In the scenario of transporting acidic and alkaline media, corrosion-resistant stainless steel valve bodies and special seals should be selected to avoid medium erosion causing valve body leakage and valve core jamming. In addition, establishing a regular maintenance mechanism is indispensable. It is necessary to conduct sealing and action response tests on micro solenoid valves according to the operation cycle of the assembly line, replace aging seals and coils in a timely manner, and avoid the risk of failure in advance.

In summary, micro solenoid valves provide core support for the efficient operation of industrial automation assembly lines, and their application effectiveness and protection level are directly related to the stability and economy of the assembly line. Enterprises need to accurately select and adapt micro solenoid valves based on the specific working conditions of the assembly line, and establish a full process control system of "selection and adaptation installation protection regular maintenance". In the future, with the integration of intelligent technology, micro solenoid valves with status self-monitoring function will further improve the efficiency of assembly line operation and maintenance, injecting stronger impetus into the development of industrial automation.

Prev:Electric Proportional Valve: Precisely Regulating Fluids to Empower Industrial Automation

Next:What specific inspection items are usually included in conductivity testing?