In the industrial automation system, the regulation of fluid (hydraulic oil, compressed air, etc.) pressure and flow directly determines equipment operation accuracy and production efficiency. As a core component connecting electrical signals and fluid control, the electric proportional valve, with its precise conversion capability between "electrical signals and fluid parameters", has broken the extensive control mode of traditional on-off valves, becoming a key enabler of precise control in industrial automation. It is widely used in precision manufacturing, robotics, construction machinery and other fields.

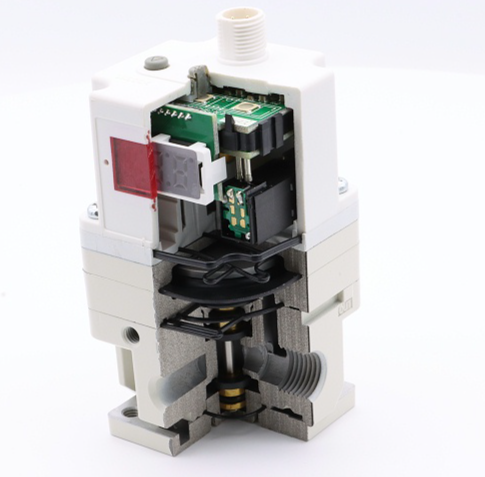

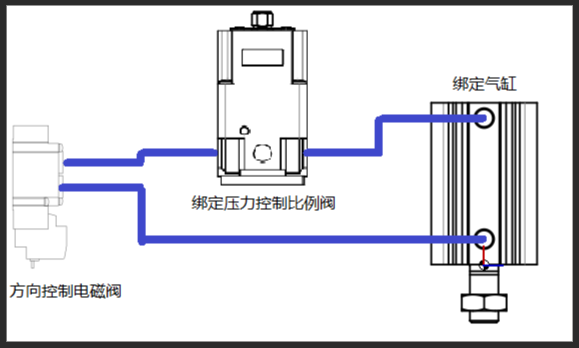

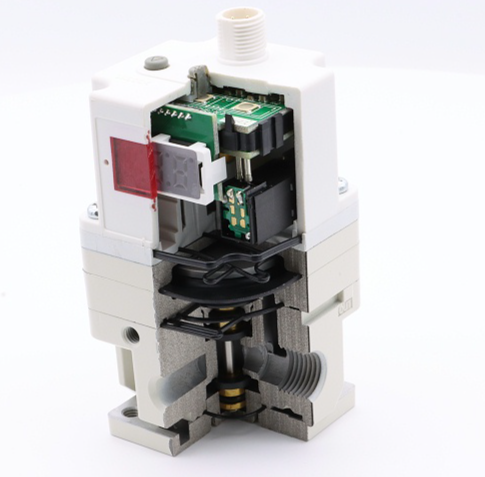

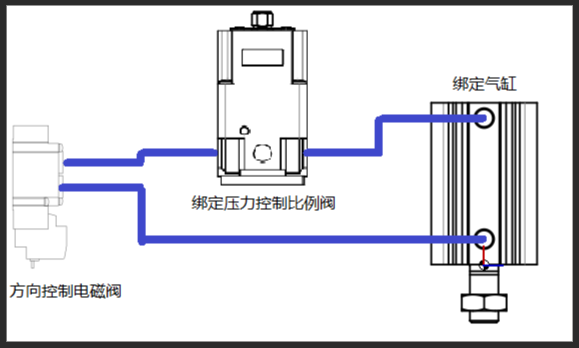

The core logic of the electric proportional valve to achieve precise regulation lies in proportional adjustment of fluid parameters through electrical signals. Its working principle is based on the coordinated conversion of "electricity - machinery - hydraulics": the analog signal output by the controller (such as 0-10V voltage or 4-20mA current) is received by the proportional electromagnet inside the valve. The electromagnet converts the electrical signal into a proportional mechanical force to drive the spool displacement. The spool displacement has a linear corresponding relationship with the input electrical signal, thereby precisely controlling the opening size of the valve port and ultimately realizing the continuous adjustability of fluid pressure and flow. This closed-loop control chain of "electrical signal command - spool displacement - fluid parameters" ensures the high precision and repeatability of fluid regulation, with an error controlled within ±1%, which is far superior to the discrete control effect of traditional on-off valves.

Innovations and upgrades in core technologies have further enhanced the precise control capability of electric proportional valves. In terms of the drive mechanism, high-performance proportional electromagnets and feedback-type spool designs are adopted. Displacement sensors real-time monitor the spool position to form closed-loop control, effectively compensating for errors caused by mechanical wear and oil temperature changes, and ensuring the precise matching between valve port opening and electrical signals. In the design of internal valve flow channels, Computational Fluid Dynamics (CFD) simulation optimization is applied to reduce flow resistance and turbulence effects, improve the stability of fluid flow, and make flow regulation smoother and pressure control more precise. In addition, some high-end products integrate digital control modules, supporting online parameter adjustment and fault self-diagnosis. Through algorithm optimization, the dynamic response speed is improved, with a response time as low as 10ms, meeting the control needs of high-speed precision equipment.

The precise regulation capability of electric proportional valves provides diversified value empowerment for industrial automation scenarios. In the field of precision manufacturing, such as injection molding machines and machine tool processing, it can precisely control the movement speed and pressure of hydraulic actuators, ensuring product molding accuracy and processing tolerances. In the field of industrial robotics, through precise flow distribution in the joint-driven hydraulic system, it achieves the stability and positioning accuracy of robot movements, improving work efficiency. In the field of construction machinery, such as excavators and cranes, it can dynamically adjust the hydraulic system pressure according to load changes, ensuring operation force while reducing energy consumption, and achieving a balance between energy saving and high efficiency. Compared with traditional control methods, the application of electric proportional valves increases equipment control accuracy by more than 30% and reduces energy consumption by 15%-20%, becoming a core support for industrial automation upgrades.

With the advancement of Industry 4.0, electric proportional valves are evolving towards digitalization, integration, and intelligence. In the future, by integrating industrial internet and IoT technologies, real-time monitoring and remote regulation of valve status will be realized. Combined with artificial intelligence algorithms, control parameters can be automatically optimized according to working conditions, further improving adaptability and control precision. Meanwhile, miniaturization and lightweight design will make it more suitable for the needs of compact equipment. As the "fluid control center" of industrial automation, the technological progress of electric proportional valves will continue to drive industrial production towards a more precise, efficient, and energy-saving direction, providing a solid technical guarantee for the construction of intelligent manufacturing systems.

Prev:quick-disconnectFittings: Simplify Installation Steps and Enhance Connection Stability

Next:Micro electromagnetic valve: application and protection strategy in industrial automation assembly line