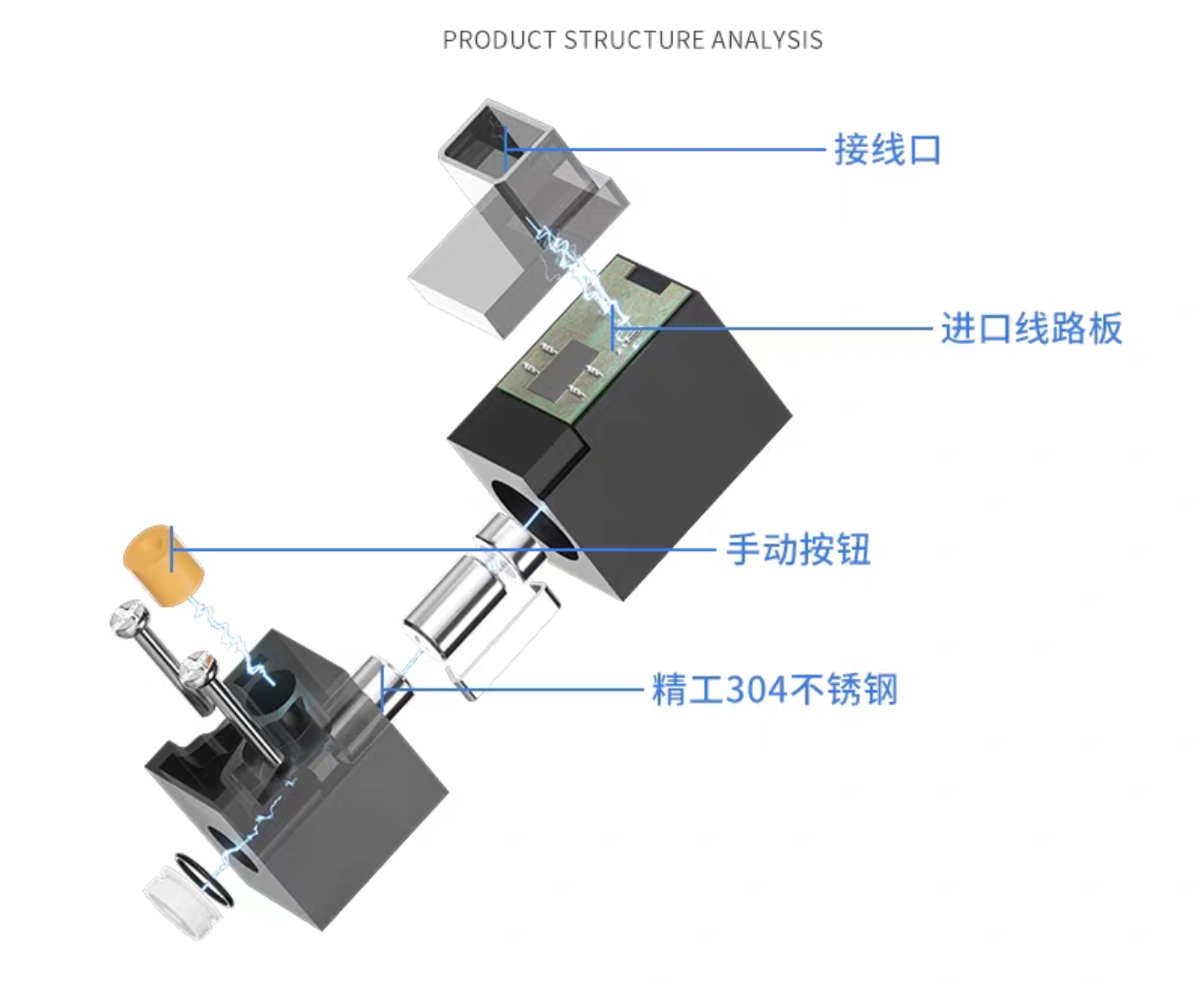

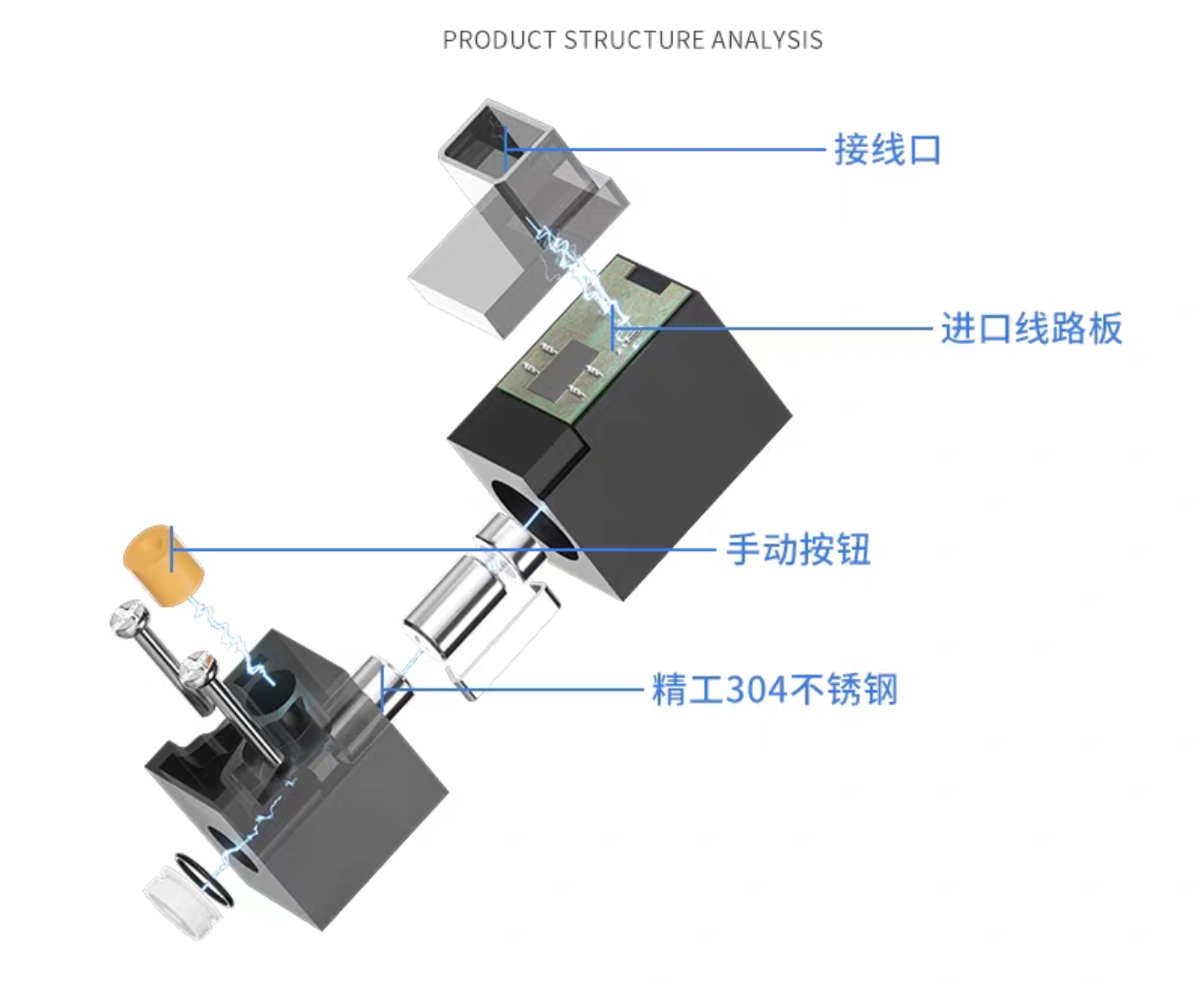

In the modern industrial system, solenoid valves—automated components that control the on-off state of fluids using electromagnetic principles—have become indispensable core equipment in critical fields such as aviation, military industry, and automotive engineering, thanks to their fast response, precise control, and high reliability. By controlling the movement of the valve core through the energization and de-energization of electromagnetic coils, they achieve accurate regulation of fluids like liquids and gases. This not only supports the stable operation of equipment in various fields but also plays an irreplaceable role in improving system efficiency and ensuring safety performance.

In the aviation field, the "high reliability" and "extreme environment adaptability" of solenoid valves are key to ensuring the safe flight of aircraft. During flight, aircraft are exposed to complex working conditions such as low temperatures at high altitudes, large pressure differences, and strong vibrations, imposing extremely strict performance requirements on components. Aviation-grade solenoid valves are made of lightweight, high-strength materials, enabling stable operation within an extreme temperature range of -55°C to 150°C. They also possess excellent vibration and impact resistance, effectively preventing valve core jamming or seal failure caused by changes in working conditions. In the hydraulic system of aircraft, solenoid valves control the flow direction and pressure of hydraulic oil, accurately adjusting critical movements such as landing gear retraction/extension and wing flap deflection; their millisecond-level response speed ensures the timeliness of flight attitude adjustments. In the fuel system, solenoid valves optimize engine combustion efficiency by precisely controlling fuel injection volume, which not only enhances power output but also reduces fuel consumption and emissions, providing solid support for the safe and efficient flight of aircraft.

The military industry has even higher requirements for solenoid valves in terms of "harsh environment resistance" and "anti-interference capability." Military equipment often needs to perform tasks in extreme environments such as deserts, plateaus, and oceans, and may face complex situations like electromagnetic interference and artillery impact. Military-grade solenoid valves adopt special sealing structures and anti-corrosion coatings, which can effectively resist sand and dust intrusion as well as seawater corrosion, maintaining stable performance in high-temperature, low-temperature, and high-humidity environments. For example, in the hydraulic transmission system of military armored vehicles, solenoid valves must accurately control the distribution of hydraulic oil under severe vibration and impact to ensure the flexibility of vehicle movement and weapon system rotation. In shipborne weaponry, salt spray-resistant solenoid valves guarantee the fluid control accuracy of missile launch systems and naval gun feeding systems, preventing equipment failures from affecting combat effectiveness. Additionally, military-grade solenoid valves are designed with anti-electromagnetic interference capabilities, allowing them to work normally in strong electromagnetic environments and ensuring the coordinated stability of the electronic systems and fluid control systems of military equipment.

In the automotive field, solenoid valves focus on "high efficiency and energy saving" as well as "safety adaptation," becoming important components of automotive power systems and control systems. With the transformation of the automotive industry towards new energy and intelligence, the application scenarios of solenoid valves continue to expand, and their functional requirements are becoming increasingly diverse. In the engine of traditional fuel vehicles, solenoid valves optimize the combustion process by controlling the injection timing and volume of fuel injectors, improving engine power performance and reducing exhaust emissions. In automatic transmissions, they regulate the pressure and flow direction of hydraulic oil to achieve smooth gear shifts, enhancing driving comfort. In new energy vehicles, solenoid valves play an even more critical role: in the battery thermal management system, they accurately adjust the battery temperature by controlling the circulation path and flow rate of coolant, ensuring the battery operates within the optimal temperature range and extending its service life. In hydrogen fuel cell vehicles, solenoid valves in the hydrogen supply system must have high airtightness to prevent hydrogen leakage and ensure the safe and stable operation of fuel cells. Meanwhile, automotive solenoid valves must also meet the requirements of lightweight and low power consumption to adapt to the vehicle's needs for energy consumption control and spatial layout, helping the automotive industry achieve energy conservation and emission reduction goals.

With continuous technological iteration, solenoid valves are developing towards intelligence and integration. Some high-end solenoid valves have integrated sensors and data transmission modules, which can real-time monitor parameters such as valve core position, fluid pressure, and operating temperature, and upload the data to the control system to realize fault early warning and remote diagnosis, further improving system reliability and maintenance efficiency. In the aviation field, intelligent solenoid valves can assist aircraft in implementing health management and detect potential faults in advance. In the automotive field, integrated solenoid valve modules can reduce system volume and weight, adapting to the compact layout requirements of new energy vehicles.

In summary, as core components for fluid control, solenoid valves play an irreplaceable role in aviation, military industry, automotive, and other fields. They are not only the "control center" for the stable operation of equipment in various fields but also an important support for promoting technological upgrading and improving safety performance and efficiency. As industries continue to increase their demand for automated and precise control, solenoid valves will keep innovating and developing, empowering the high-quality development of more fields.

Prev:Working Principle of Automotive Wiring Harness Test Bench

Next:quick-disconnectFittings: Simplify Installation Steps and Enhance Connection Stability